![]() TEL 02-420-5356

TEL 02-420-5356

Polystyrene Foam (PS)

EPS Foam used by most of the manufacture for all industrial as a “Best Value” and sustainable investment.

| Core Type | Expanded Polystyrene Foam(EPS),Self-extinguish Grade |

| Insulation Density | 16 , 20 , 32 Kg/M 3 |

| Thermal conductivity coefficient (K) | 0.029-0.033 W/mK (DIN 52612) |

| Fire Behavior | Extinguish in 1 second (ASTM D568, D635) |

| Operating Temperature | -80 °C to 85 °C |

| Skin Material | Corrosion Coating | Base Metal Thickness(mm) | Standard | Top Paint Type | Top Thickness | Food Grade | Antibacterial | Color |

| SD TM (Zinc -aluminum-magnesium G300 steel) | ZM180 | 0.40,0.50,0.55 | AS1397,AS2728 | Polyester | 25 μm | ✔ | ✔ | Off white |

| GIX TM (Zinc -aluminum-magnesium G300 steel) | ZM180 | 0.45 | AS1397,AS2728 | Polyester | 28 μm | ✔ | ✔ | Milky white |

| GI Panel SD G-300 (Zinc-aluminum- magnesium G300 steel) | ZM120 | 0.35 | AS1397 | Polyester | 28 μm | ✔ | - | Milky white |

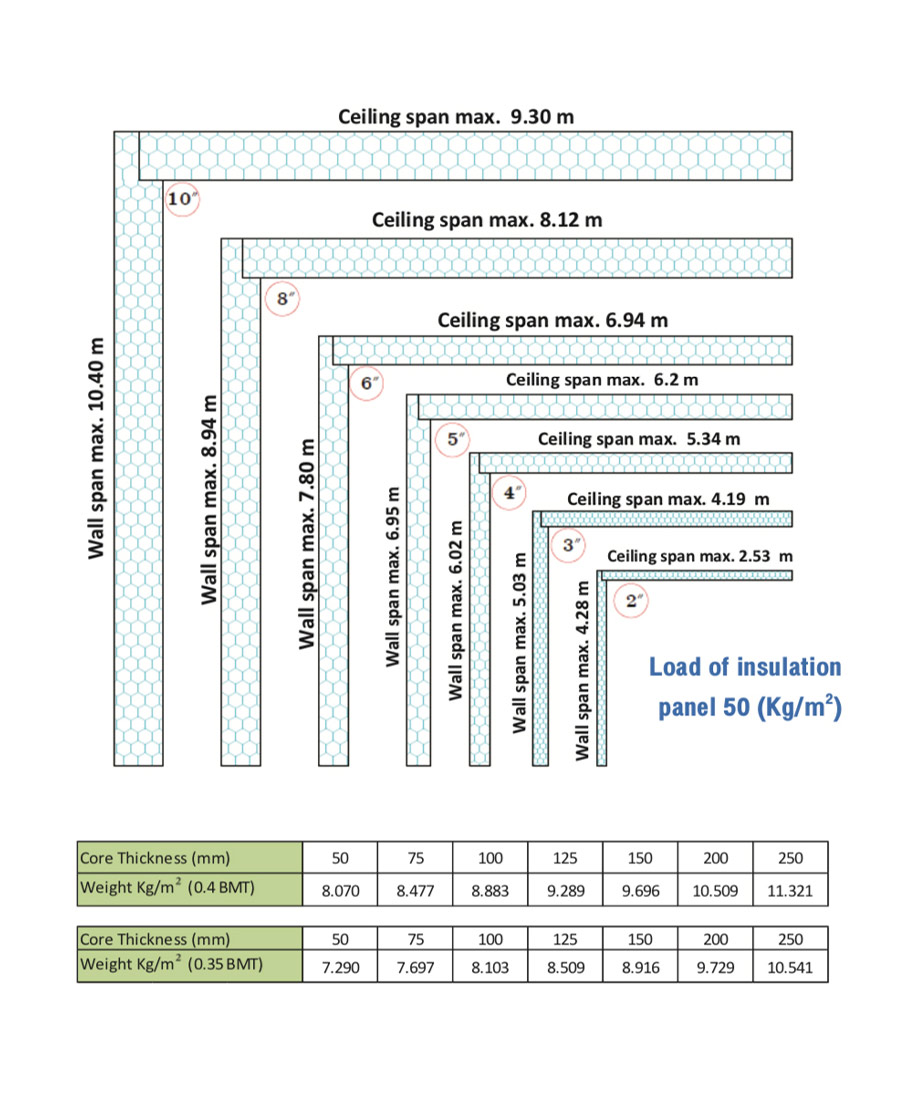

Maximum Wall & Ceiling Spans (for density 1 lb/ft3)

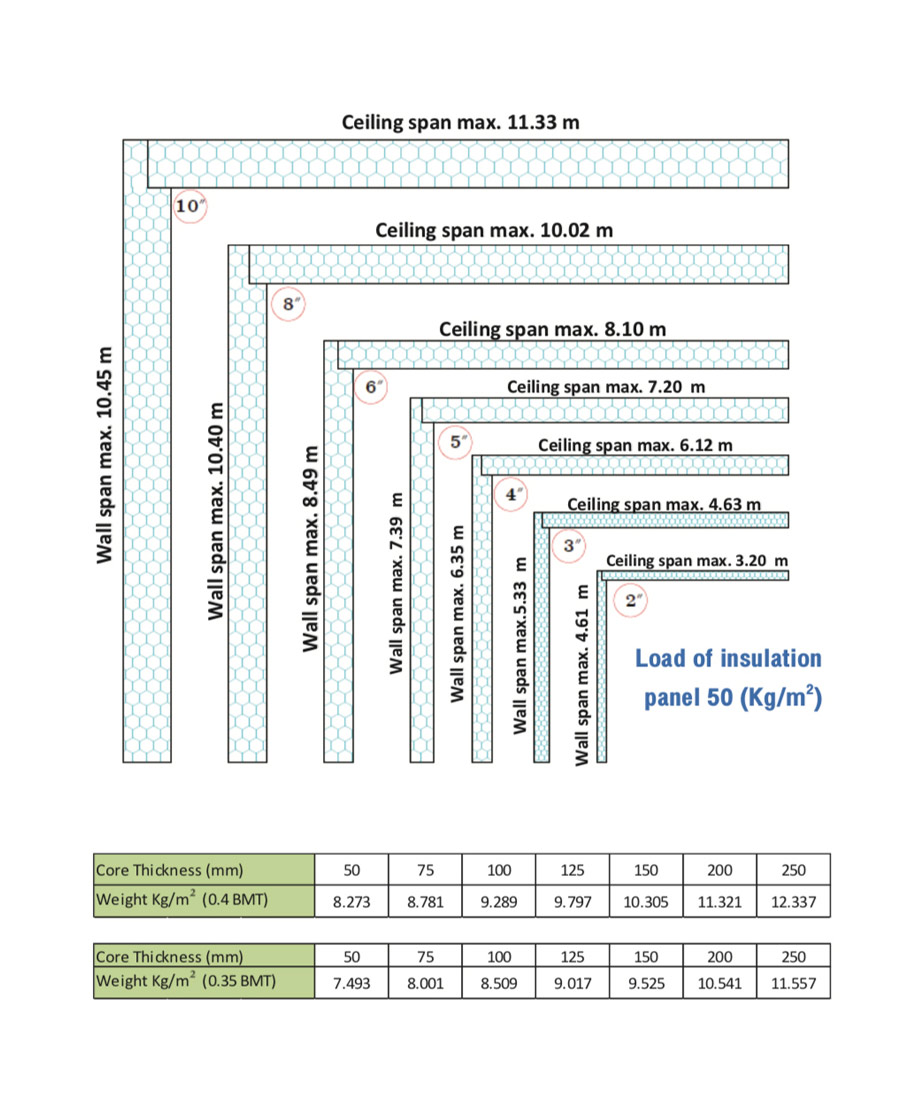

Maximum Wall & Ceiling Spans (for density 1.25 lb/ft3)

Brand Feature

Functions

- PS panels are ASTM (American Society for Testing and Materials) certified and conform to the specifications

- Improved compressive strength with its vertical sides

Construction

- Easy to assemble and reinstall

Performance

- Lightweight

- Fireproof panel

- Long lifetime, worthwhile investment

Value

- Excellent Lock system super strength and flexibility

- Without using rivets

Operating Temperature

| Operating Temperature | Recommended Thickness / PIR |

| 20 to 16 | 2” (50) |

| 15 to 10 | 3” (75) |

| 9 to 0 | 4” (100) |

| - 1 to - 8 | 5” (125) |

| - 9 to - 15 | 6” (150) |

| - 16 to -32 | 8” (200) |

| -33 to - 40 | 10” (250) |

| - 41 to - 50 | 12” (300) |

R-Value , U-Value

| Thickness (mm) | R-Value (M 2 K/W) / PSF | U-Value (W/M 2 K) / PSF |

| 2" (50) | 1.150 | 0.660 |

| 3" (75) | 2.273 | 0.440 |

| 4" (100) | 3.030 | 0.330 |

| 5" (125) | 3.788 | 0.264 |

| 6" (150) | 4.545 | 0.220 |

| 8" (200) | 6.061 | 0.165 |

| 10" (250) | 7.576 | 0.132 |

| 12" (300) | 9.091 | 0.110 |

Heat Transmission

| Insulation thickness (Inch) | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| Insulation thickness (mm) | 50 | 75 | 100 | 125 | 150 | 200 | 250 | 300 |

| Temperature Difference (°C) | ||||||||

| 5 | 3.300 | 2.200 | 1.650 | 1.320 | 1.100 | 0.825 | 0.660 | 0.550 |

| 10 | 6.600 | 4.400 | 3.300 | 2.640 | 2.200 | 1.650 | 1.320 | 1.100 |

| 15 | 9.900 | 6.600 | 4.950 | 3.960 | 3.300 | 2.475 | 1.980 | 1.650 |

| 20 | 13.200 | 8.800 | 6.600 | 5.280 | 4.400 | 3.300 | 2.640 | 2.200 |

| 25 | 16.500 | 11.000 | 8.250 | 6.600 | 5.500 | 4.125 | 3.300 | 2.750 |

| 30 | 19.800 | 13.200 | 9.900 | 7.920 | 6.600 | 4.950 | 3.960 | 3.300 |

| 35 | 23.100 | 15.400 | 11.550 | 9.240 | 7.700 | 5.775 | 4.620 | 3.850 |

| 40 | 26.400 | 17.600 | 13.200 | 10.560 | 8.800 | 6.600 | 5.280 | 4.400 |

| 45 | 29.700 | 19.800 | 14.850 | 11.880 | 9.900 | 7.425 | 5.940 | 4.950 |

| 50 | 33.000 | 22.000 | 16.500 | 13.200 | 11.000 | 8.250 | 6.600 | 5.500 |

| 55 | 36.300 | 24.200 | 18.150 | 11.520 | 12.100 | 9.075 | 7.260 | 6.050 |

| 60 | 39.600 | 26.400 | 19.800 | 15.840 | 13.200 | 9.900 | 7.920 | 6.600 |

| 65 | 42.900 | 28.600 | 21.450 | 17.160 | 14.300 | 10.725 | 8.580 | 7.150 |